The classic torque measuring shaft, as often used in test benches, presents numerous challenges. It is usually mounted on bearings and often equipped with slip rings, which leads to increased wear and undesirable force shunting. In addition, mounted measuring shafts require a bearing block and elastic couplings on both sides, which makes test bench operation more complex and less efficient. The bearing noise is also particularly disruptive and can be problematic in sensitive test applications.

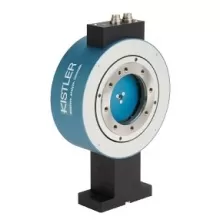

The MANNER torque measuring shaft is based on state-of-the-art sensor telemetry. The torque signal is recorded using strain gauges and digitized by a high-precision measuring amplifier mounted on the shaft. This operates with a resolution of 16 bits and enables contactless signal transmission via an antenna gap of up to 10 mm. This means that installation remains unproblematic both radially and axially.

The bearingless torque measuring shaft from MANNER Sensortelemetrie offers a superior alternative here. By eliminating bearings and couplings, not only is the test bench design more compact and economical, but the measurement accuracy is also significantly improved.